Transform paperboard into high-end collectibles that command premium shelf prices.

Transform paperboard into high-end collectibles that command premium shelf prices.

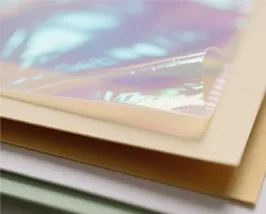

How to achieve highly three-dimensional embossing (raised and recessed) effects?

We employ 3D embossed hot stamping technology and multi-level progressive pressure control, enabling precise depth adjustment while maintaining sharp, blur-free graphic contours.

How do you prevent foil peeling or smudging, especially with laser foil stamping?

Jiexiang equipment features ±1℃ precision temperature control and electronic peel technology, ensuring flawless foil transfer and secure adhesion. An optional wear-resistant varnish coating unit can be integrated post-processing to significantly enhance scratch resistance.

Can small-batch, high-end custom orders be fulfilled while maintaining cost control?

Get expert solution.

+86 15858768887

I am Online now

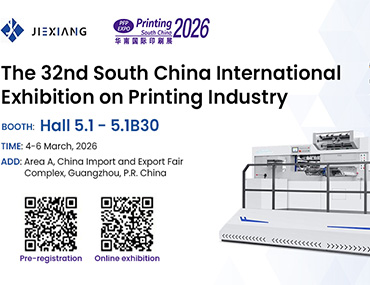

Does JIEXIANG offer customization services?

🟢 Online | Privacy policy