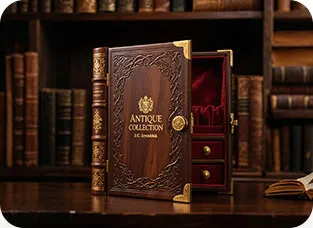

Mastery in cutting and stamping intricate shapes on luxury gift boxes and rigid boards with zero crush or deformation.

Mastery in cutting and stamping intricate shapes on luxury gift boxes and rigid boards with zero crush or deformation.

How do we ensure creasing precision and forming quality for complex box types (such as lid-and-base boxes, drawer boxes)?

We employ precision creasing blades and pressure control systems to ensure clean, uniformly deep creases. This guarantees effortless folding and sharp edges during automated gluing.

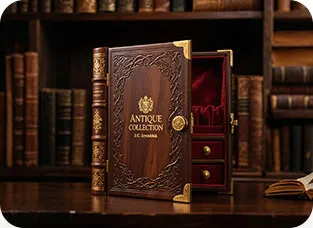

How do we achieve precise registration between surface effects like spot UV and tactile inks with die-cutting/foil stamping?

Our equipment platform supports optical registration mark tracking, ensuring registration accuracy within ±0.1mm between different process units.

How do we optimize designs to minimize material waste and control costs?

We provide professional layout software interfaces and die-cutting design consulting to help you achieve optimized nested layouts, minimizing material loss during the die-cutting process.

Get expert solution.

+86 15858768887

I am Online now

Does JIEXIANG offer customization services?

🟢 Online | Privacy policy