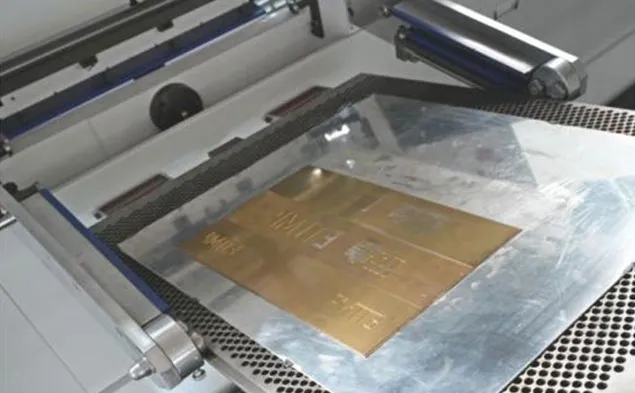

The JX-1060T/JX-1060TZ Fully Automatic Platen Foil Stamping/Die-cutting (dual-purpose) Machine features comprehensive hardware configurations, enabling it to adapt to the foil stamping requirements of the vast majority of products.

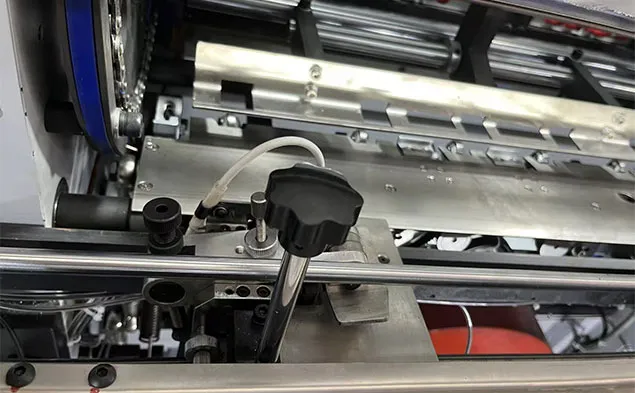

Automatic paper aligner and dual-path air blowing device at the delivery ensure neat stacking for both thick and thin paper.

Touchscreen control at the delivery section facilitates operation with numerical display; all operations can be completed via touch.

The delivery section is equipped with a control panel for more humanized operation.

Photoelectric detection at the delivery ensures neat paper stacking.

Automatic lifting/lowering control system for the delivery pile.

Main chain protection device.

Anti-paper-retraction device (prevents paper from moving backward).

Equipped with a non-stop unit (for continuous operation).

The delivery section can control the entire machine via a 10.4-inch touchscreen.

| Name | JX-1060T (Normal) | JX-1060TZ (Emboss) |

|---|---|---|

| Max. feeding paper size | 1060×750mm | 1060×750mm |

| Min. feeding paper size | 400×360mm | 400×360mm |

| Max.die-cutting area | 1040×720mm | 1040×720mm |

| Max. foil stamping area | 1040×720mm | 1040×720mm |

| Gripper margin | 8-17mm | 8-17mm |

| Plate frame size | 1080×745mm | 1080×745mm |

| Paper specifications | 80-2000g/m² (cardboard) | 80-2000g/m² (cardboard) |

| ≤4mm (thickness of corrugated paper) | ≤4mm (thickness of corrugated paper) | |

| Die-cutting/foil stamping precision | ≤±0.1mm | ≤±0.1mm |

| Max. working pressure | 300T | 600T |

| Max. working speed | 7500s/h (die-cutting) | 7500s/h (die-cutting) |

| Max. feed pile height | 1600mm (including wooden pallets) | 1600mm (including wooden pallets) |

| Max. delivery pile height | 1400mm (including wooden pallets) | 1400mm (including wooden pallets) |

| Max. foil length | 1200m (longitudinal) / 220m (transverse) | 1200m (longitudinal) / 220m (transverse) |

| Electric heating system | 12 temperature zones, adjustable from 40-200℃ | 12 temperature zones, adjustable from 40-200℃ |

| Foil width | 20-1020mm | 20-1020mm |

| Main motor power | 11kw | 18kw |

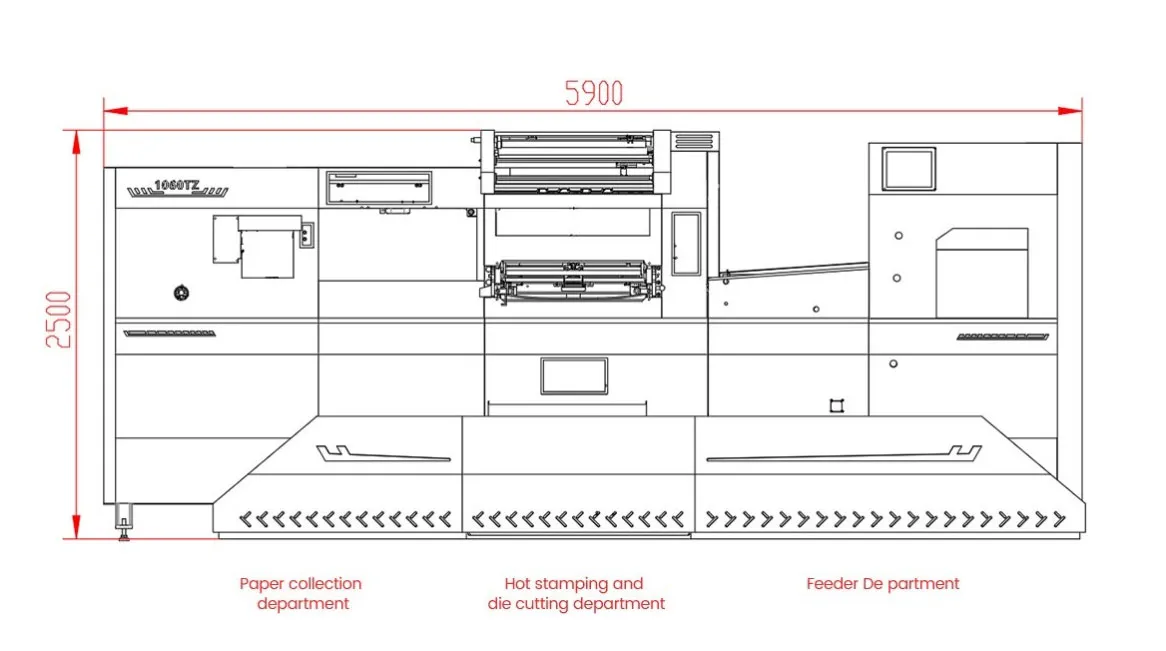

| Overall dimensions | 5900×4200 (including foot platform) ×2500mm | 5900×4200 (including foot platform)×2500mm |

| Machine weight | 17T | 20T |

| Full load power | 62kw | 69kw |

| Name | Brand | Origine | Name | Brand | Origine |

|---|---|---|---|---|---|

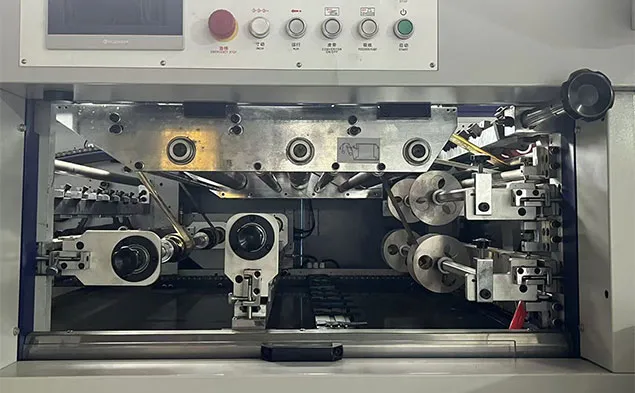

| Push Buttons | Eaton | Germany | Gripper Bars & Grippers | KUI | Japan |

| Circuit Breakers | Schneider | France | Photoelectric Sensors | SICK | Germany |

| Motor Protectors | Schneider | France | Proximity Sensors | Omron | Japan |

| AC Contactors | Schneider | France | Encoders | Omron | Japan |

| Air Circuit Breakers | Schneider | France | Sensors | Omron | Japan |

| Main Solenoid Valves | Airtac | Taiwan,China | Fiber Optics | Panasonic | Japan |

| Air Flow Regulator | Airtac | Taiwan,China | Counting Photoelectric Sensors | Omron | Japan |

| Cylindere | Airtac | Taiwan,China | Intermediate Relays | Omron | Japan |

Can foil be reused?

Foil is typically single-use. Reusing it may cause blurred patterns or damage the foil applicator.

What causes uneven foil stamping results?

Possible causes include inconsistent temperature or pressure, poor-quality foil, or unstable paper feed speed. Adjust foil stamping parameters and maintain machine cleanliness.

What materials can be foil stamped?

Common materials like paper, leather, plastic, and fabric can be foil stamped, but temperature, pressure, and speed settings must be adjusted for each material.

Get expert solution.

+86 15858768887

I am Online now

Does JIEXIANG offer customization services?

🟢 Online | Privacy policy