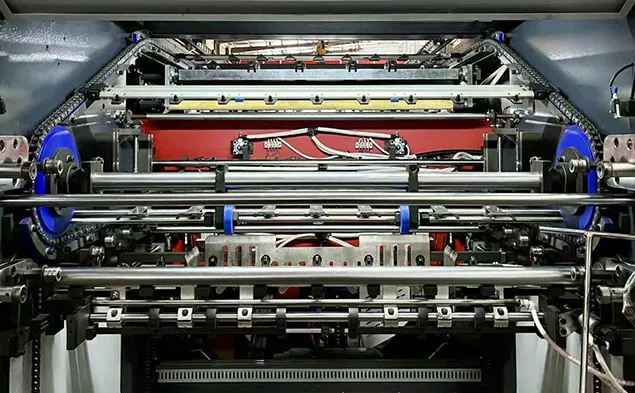

The JX-1040C Fully Automatic Flat-bed Hot Foil Stamping Machine features comprehensive hardware configurations,enabling it to adapt to the foil stamping requirements of the vast majority of products.

| Name | Parameter |

|---|---|

|

Max. feeding paper size |

1040×750mm |

|

Min. feeding paper size |

400×320mm |

|

Max. foil stamping area |

1010×720mm |

|

Gripper margin |

8-17mm |

|

Paper specifications |

105~2000g/m2(cardboard) |

|

|

≤4mm(thickness of corrugated paper) |

|

Foil stamping precision |

≤±0.15mm |

|

Max. working pressure |

200T |

|

Max. working speed |

4800s/h |

|

Max. feed pile height |

1400mm(including wooden pallets) |

|

Max. delivery pile height |

1000mm(including wooden pallets) |

|

Max. foil length |

480m (length wise) |

|

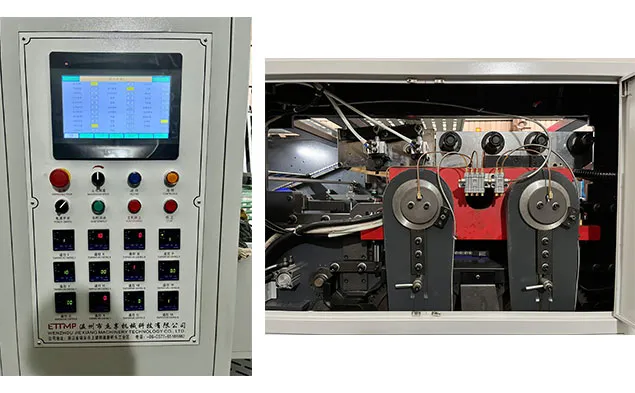

Electric heating system |

12 temperature zones,adjustable from 40-200℃ |

|

Foil width |

20-1000mm |

|

Main motor power |

7.5kw |

|

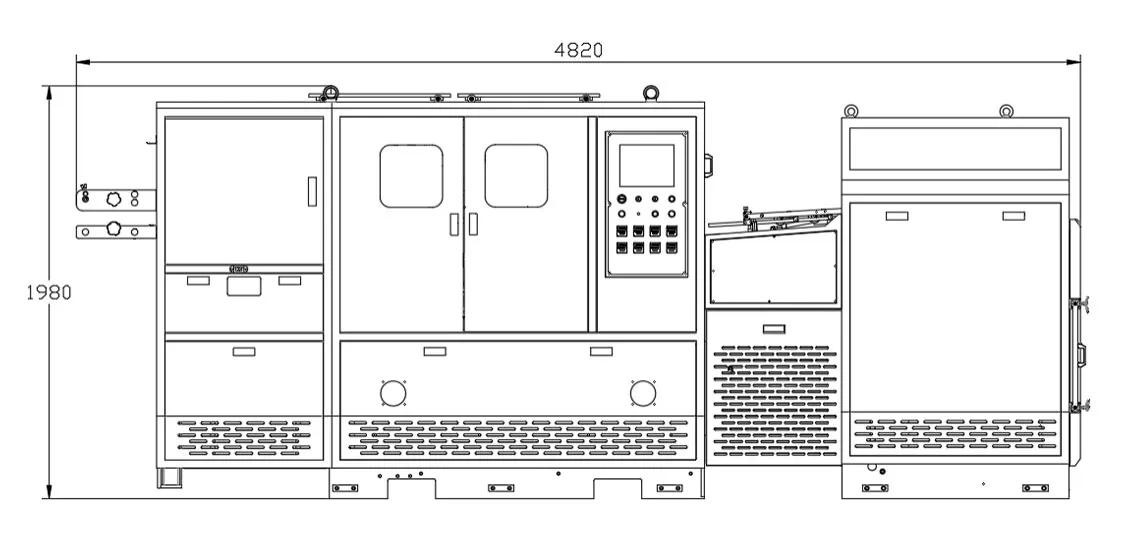

Overall dimensions |

4820(including pre-feeding paper track)×3000(including foot platform)×1980mm |

|

Machine weight |

9000kg |

|

Full load power |

34kw |

|

Working voltage |

1P/220V |

| Name | Brand | Origine | Name | Brand | Origine |

|---|---|---|---|---|---|

| Push Buttons | Eaton | Germany | Gripper Bars & Grippers | KUI | Japan |

| Circuit Breakers | Schneider | France | Photoelectric Sensors | SICK | Germany |

| Motor Protectors | Schneider | France | Proximity Sensors | Omron | Japan |

| AC Contactors | Schneider | France | Encoders | Omron | Japan |

| Air Circuit Breakers | Schneider | France | Sensors | Omron | Japan |

| Main Solenoid Valves | Airtac | Taiwan,China | Fiber Optics | Panasonic | Japan |

| Air Flow Regulator | Airtac | Taiwan,China | Counting Photoelectric Sensors | Omron | Japan |

| Cylindere | Airtac | Taiwan,China | Intermediate Relays | Omron | Japan |

How is die-cutting machine precision ensured?

Product dimensions and cutting accuracy are maintained through regular machine calibration, use of high-quality dies, and adjustment of cutting pressure and speed.

How often do die-cutting machine blades need replacement?

Die life depends on material and usage frequency. Paper dies typically last tens of thousands of cuts, while harder materials may require more frequent replacement.

What materials are suitable for die-cutting machines?

Die-cutting machines can process materials such as paper, cardstock, thin plastics, and thin metal sheets. However, materials with excessive thickness or hardness may require specialized dies or higher-powered models.

Get expert solution.

+86 15858768887

I am Online now

Does JIEXIANG offer customization services?

🟢 Online | Privacy policy