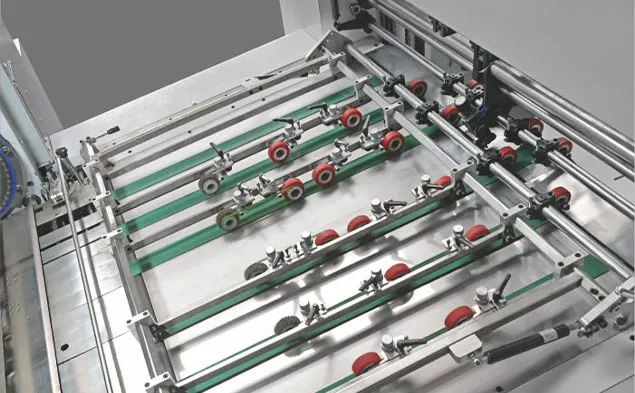

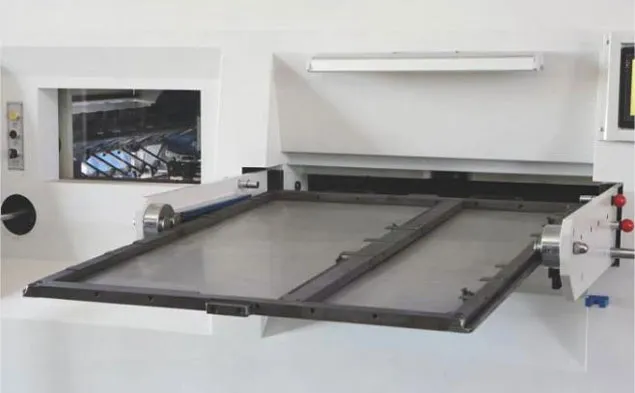

The JX-1060M/JX-1060MZ Fully Automatic Platen Die-cutting Machine features comprehensive hardware configurations, enabling it to adapt to the cutting requirements of the vast majority of products.

| Name | JX-1060M | JX-1060MZ (Heavy) |

|---|---|---|

|

Max. feeding paper size |

1060×750mm |

1060×750mm |

|

Min. feeding paper size |

400×320mm |

400×320mm |

|

Max.die-cutting area |

1020×730mm |

1020×730mm |

|

Gripper margin |

8-17mm |

8-17mm |

|

Plate frame size |

1080×745mm |

1080×745mm |

|

Paper specifications |

80-2000g/m2 (cardboard) |

80-2000g/m2 (cardboard) |

|

≤4mm (thickness of corrugated paper) |

≤4mm (thickness of corrugated paper) | |

|

Die-cutting precision |

≤±0.1mm |

≤±0.1mm |

|

Max. working pressure |

300T - 600T |

300T - 600T |

|

Max. working speed |

7500s/h (die-cutting) |

7500s/h (die-cutting) |

|

Max. feed pile height |

1600mm (including wooden pallets) |

1600mm (including wooden pallets) |

|

Max. delivery pile height |

1400mm (including wooden pallets) |

1400mm (including wooden pallets) |

|

Main motor power |

11kw-18kw |

11kw-18kw |

|

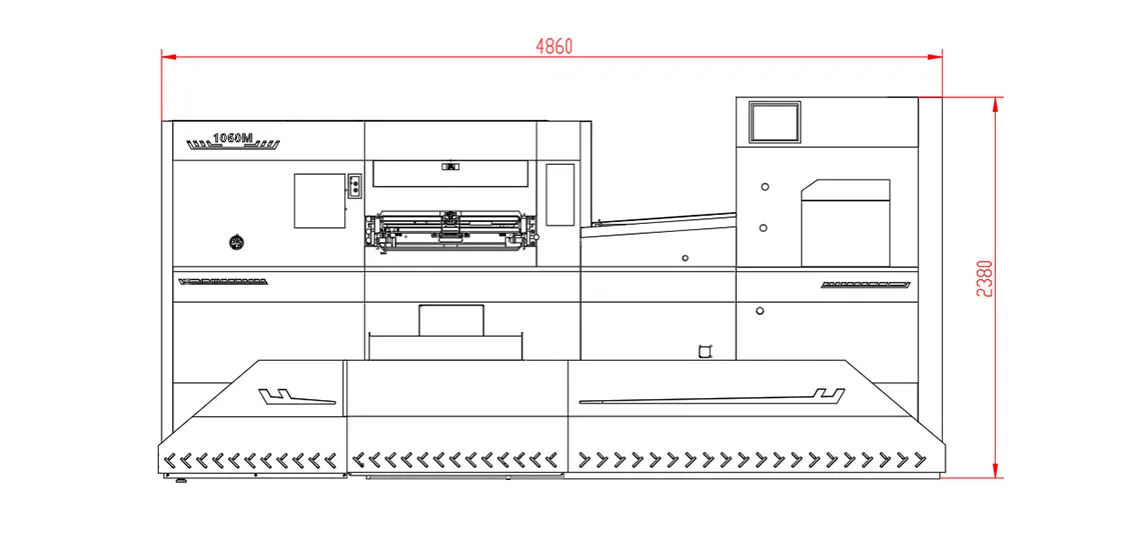

Overall dimensions |

4900×4000 (including foot platform)×2400mm |

4900×4000 (including foot platform)×2400mm |

|

Machine weight |

16T |

18T |

|

Full load power |

19kw-26kw |

19kw-26kw |

| Name | Brand | Origine | Name | Brand | Origine |

|---|---|---|---|---|---|

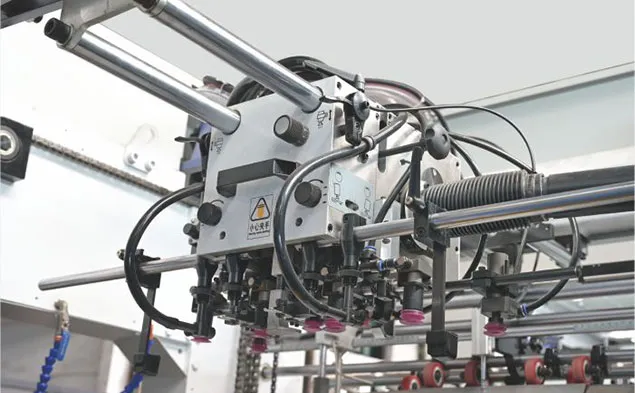

| Push Buttons | Eaton | Germany | Gripper Bars & Grippers | KUI | Japan |

| Circuit Breakers | Schneider | France | Photoelectric Sensors | SICK | Germany |

| Motor Protectors | Schneider | France | Proximity Sensors | Omron | Japan |

| AC Contactors | Schneider | France | Encoders | Omron | Japan |

| Air Circuit Breakers | Schneider | France | Sensors | Omron | Japan |

| Main Solenoid Valves | Airtac | Taiwan,China | Fiber Optics | Panasonic | Japan |

| Air Flow Regulator | Airtac | Taiwan,China | Counting Photoelectric Sensors | Omron | Japan |

| Cylindere | Airtac | Taiwan,China | Intermediate Relays | Omron | Japan |

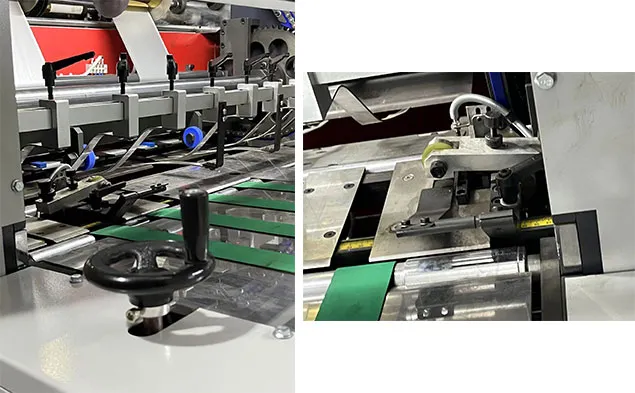

Does processing thick materials affect foil stamping on the all-in-one machine?

Excessively thick materials may impact cutting depth and foil stamping uniformity. We recommend adjusting pressure settings based on material thickness or processing in two stages.

Is maintenance complex for the all-in-one machine?

Compared to single-function machines, the structure is slightly more complex. However, regular cleaning of the cutting head and foil stamping head, along with lubricating moving parts, ensures long-term stable operation

How does the all-in-one machine switch between die-cutting and foil stamping functions?

Select the function mode via the control panel, or install the corresponding cutting blade/foil stamping head to switch. Both functions can be performed on the same machine.

Get expert solution.

+86 15858768887

I am Online now

Does JIEXIANG offer customization services?

🟢 Online | Privacy policy