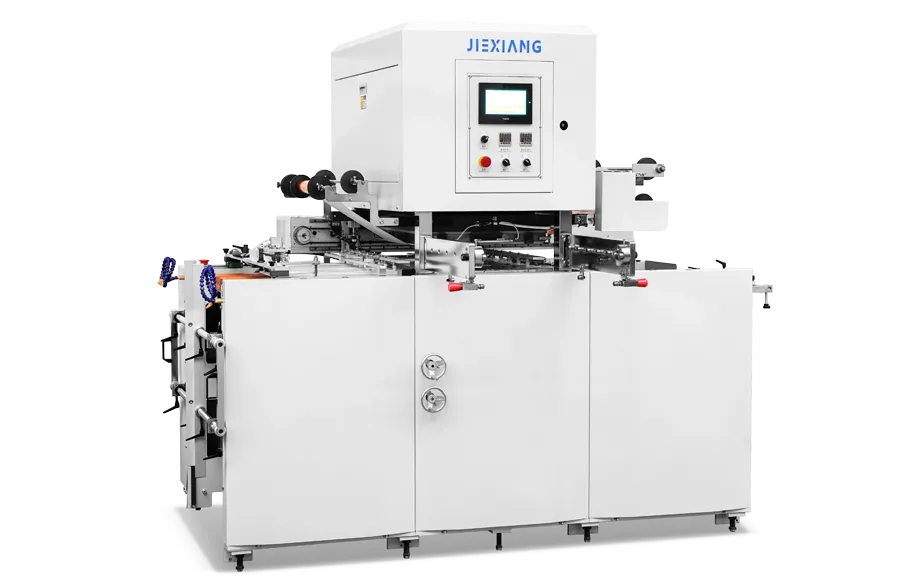

- All castings are made of QT600-7 ductile iron for high strength.

- An intermittent mechanism imported from Taiwan ensures precise machine movement.

- The entire machine utilizes components imported from Mueller, Omron, Schneider, and Panasonic.

- The crankshaft is made of German nickel-chromium-molybdenum diamond for high precision.

- Pneumatic components from Taiwan Airtac ensure precise movement.

- The side gauges utilize a Panasonic photoelectric system.

- The main PLC uses Inovance Technology (stock code 300124) to ensure smooth machine operation.

- A centerline positioning system enables quick sheet changeovers.

- Equipped with a Jiexiang automatic pressure adjustment control device, it ensures fast and accurate adjustment of die-cutting pressure.

- A Chinese and English touchscreen interface is available.

- A double sheet detector is used.

- The paper delivery table features an automatic auxiliary paper delivery function for non-stop operation.

- The side gauges utilize a Panasonic photoelectric system.

- Automatic oiling system. The oil pump utilizes an automatic cooling fan.