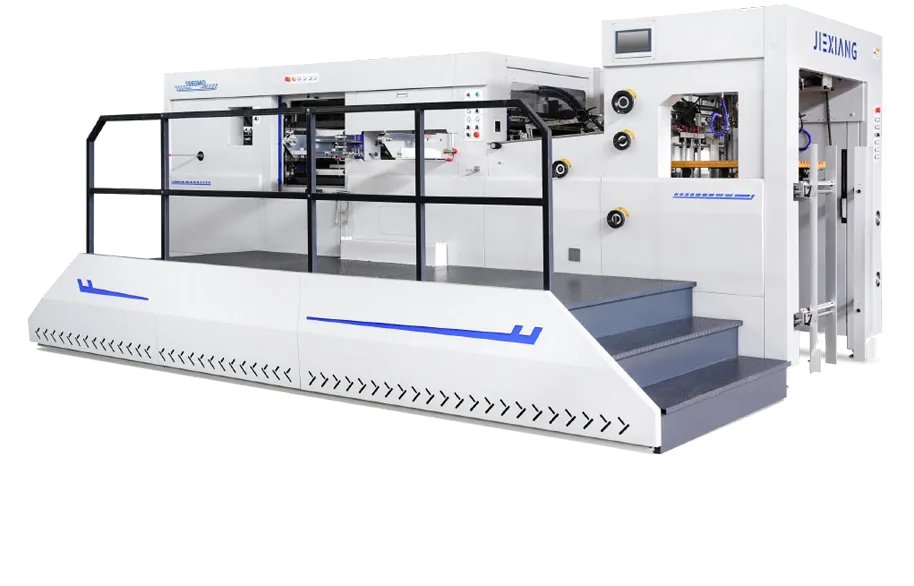

- Main unit employs imported genuine bearings.

- International components: Rexroth (German), Omron (Japan), Schneider (France), Panasonic (Japan).

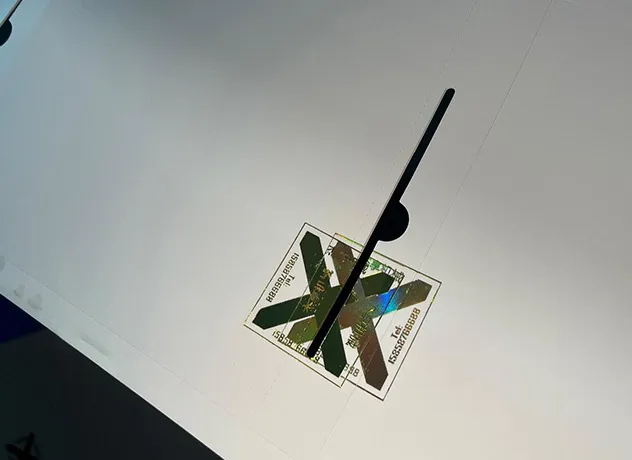

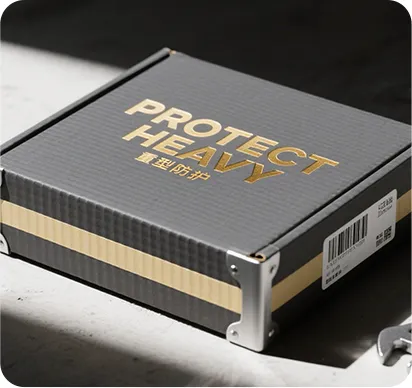

- Die cutting and waste stripping accuracy: ±0.1mm; Maximum speed: 7,500 sheets/hour.

- The crankshaft is made of German nickel-chromium alloy steel, offering high precision and permanent deformation resistance.

- Employs a centerline positioning system for rapid job changeovers.

- Features Jiexiang’s automatic pressure adjustment system for swift and precise stamping pressure control.

- Employs a double-sheet detector.

- The delivery unit features an automatic auxiliary delivery function for non-stop operation.

- Side inspection adopts Panasonic photoelectric system.

- Automatic lubrication system.

- Oil pump equipped with auto-cooling fan device.

- The main PLC uses Inovance Technology (Stock Code: 300124) to ensure smooth machine operation.

- Vacuum pump employs German Becker to ensure smooth feeder paper transport.