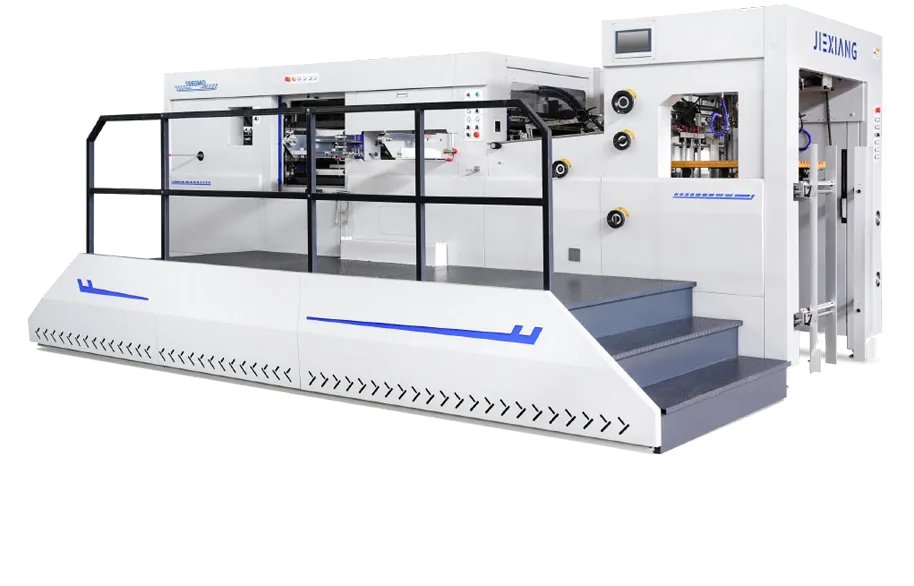

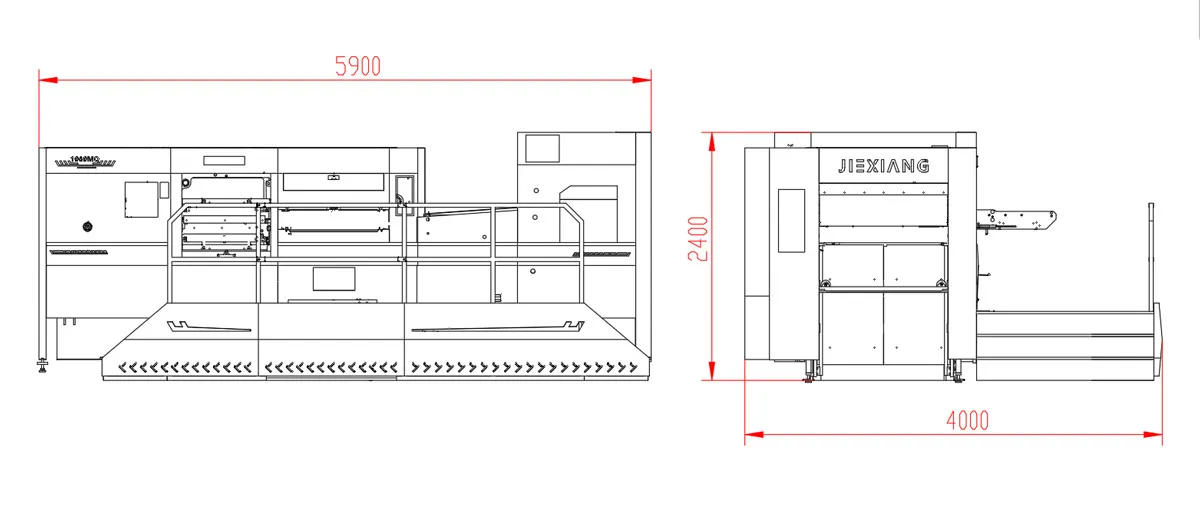

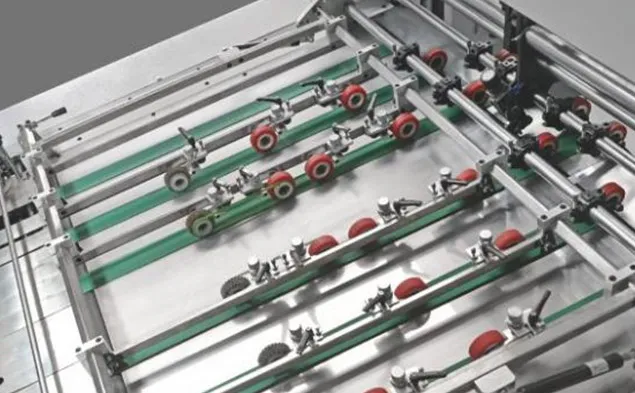

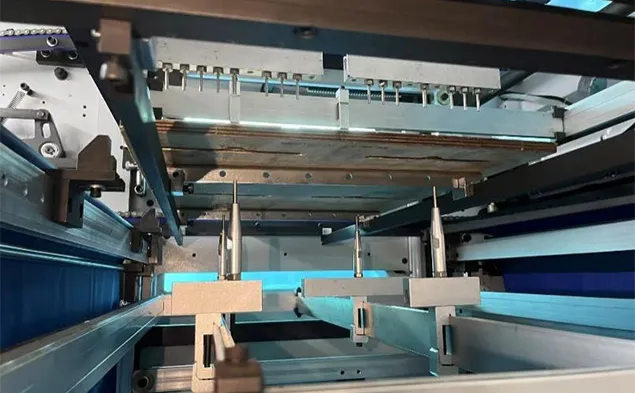

This machine is die cutting,indentation of various paper, plastic sheet, plate special equipment.

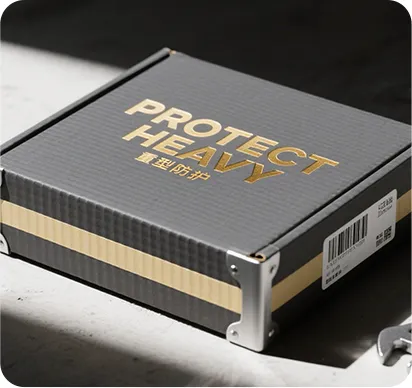

This machine is die cutting indentation of various paper, plastic sheet cutting machine, suitable for a variety of high-grade fine prints, exquisite and beautiful packaging, flat decoration products.