Modern automatic die-cutting machine is no longer a luxury, but a necessity for the packaging industry to remain competitive. This article will demystify the process, providing expert insights into how these machines work, their practical advantages, and key considerations for purchasing – focusing on the real-world benefits that brands like Jiexing bring to factories. We'll explore real-world examples, debunk some misconceptions, and provide the insights you need to make an informed investment.

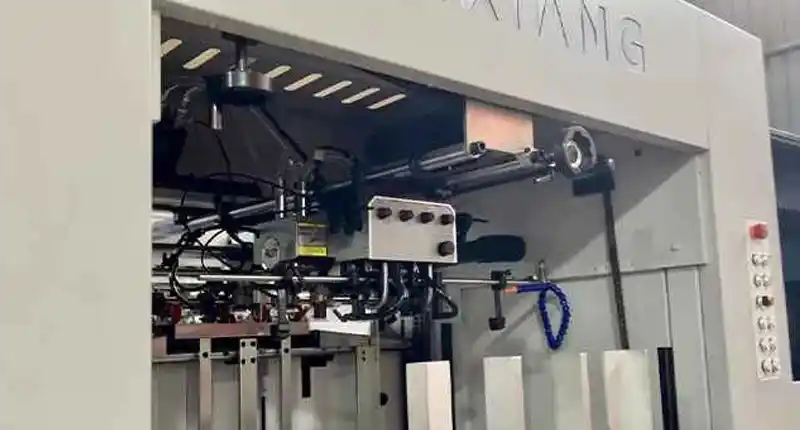

Modern automatic carton die-cutting machines integrate a continuous feeding system, often equipped with a pre-feeding unit for separating and aligning the sheets. The paper is fed into the die-cutting section, where a die mounted on a moving platen moves downwards with immense and uniform pressure. The material is perfectly cut and creased in an instant. Subsequently, the waste skeleton (the negative space around the shape) is automatically removed, and the finished, flattened carton blanks are neatly stacked at the output end. This seamless cyclical process is typically synchronized with upstream carton production die-cutting machines and downstream folding and gluing machines, forming a continuous, high-speed production line. This is a world away from semi-automatic models – like the difference between a manual water pump and a pressurized municipal water supply system.

Manually operated machines are inevitably prone to errors. Even slight misalignment can lead to waste – cartons that cannot be folded correctly, compromising the integrity of a client's high-end products. Automated systems completely solve this problem. Every sheet is precisely positioned and cut with microscopic accuracy. For brands like Jiexing, this precision is engineered into the core of the machine's design, utilizing high-quality linear guides and digital positioning systems to achieve this. This means significantly reduced material waste – a direct cost saving on increasingly expensive cardboard – and no compromise on the quality of the final product.

Anyone can sell you an automatic carton die-cutting machine. A true partner provides solutions. Walking into a medium-sized packaging plant, I saw their dilemma: they had purchased an "off-the-shelf" standard machine that almost perfectly fit their unique mix of short and long-run orders, but not quite. It was like trying to force a square peg into a round hole. Choosing an automatic die-cutting machine is a significant capital decision. Let's set aside the marketing hype and discuss some key considerations.

1. Throughput and Machine Speed: Don't just look at the maximum strokes per hour listed in the brochure. Ask about the stable, sustainable operating speed. Jiexiang representatives might discuss the stability of the gear and rack drive system or the robustness of the hydraulic system, which enables consistent and reliable 24/7 operation without downtime due to overheating.

2. Versatility and Tooling: How fast is the die changeover process? For factories requiring frequent workpiece changes, a quick die change system is crucial. Look for features like magnetic roller technology or quick-clamping systems that allow changeovers in minutes, not hours. This flexibility transforms your automatic die-cutting machine from a single-purpose behemoth into a flexible and efficient production tool.

3. User Experience and Control: The operating interface shouldn't require a Ph.D. to operate. A clear and intuitive touchscreen Human-Machine Interface (HMI) and recipe storage capabilities (saving settings for repetitive jobs) can save significant time. It reduces setup errors and improves team efficiency. From what I understand, Jiexiang has invested heavily in making their control systems more user-friendly, which directly translates to less training time and higher shop floor utilization.

4. Durability and Local Support: This is critical. The machine is your long-term partner. Examine the machine's build quality: the thickness of the side frames, the quality of the steel. Most importantly, delve into after-sales service. Does the supplier (like Jiexiang) have readily available spare parts and local technicians? Even the best machine is only as good as its support. Ask for a list of references and actually contact them.

5. The Future is Integrated: The future direction of automatic die-cutting machines

Standalone machines are becoming nodes in a network. The next frontier is seamlessly integrating your automatic die-cutting machine into your digital workflow. Imagine the machine "talking" to your prepress CAD system, automatically adjusting settings based on incoming files, and feeding production data (yield, waste, downtime) back to your management software. This isn't science fiction; this is Industry 4.0, and it's happening now.

Learn how Jiexiang's automatic die-cutting solutions can be customized to your unique production process. Visit our [Automatic Die-Cutting Machine Product Page] to learn about our product range, download detailed case studies, and contact one of our engineering consultants for a free on-site or online needs assessment.

SEO Keywords

automatic die-cutting machine

carton box production

box die-cutting machine

automated die-cutting