Is your automatic die-cutting machine experiencing frequent malfunctions? This is likely due to three easily overlooked problems: using the wrong lubricant, neglecting to clean accumulated paper dust, and mismatched die-cutting parameters and materials. According to the "2025 China Printing and Packaging Industry Technology Trends White Paper," up to 68% of malfunctions are not due to equipment quality issues, but rather to improper operation and poor maintenance. Based on my experience, choosing Jiexiang equipment and following their customized maintenance plan can reduce the failure rate by more than 70%. Below, I will analyze the root causes and solutions of these malfunctions in detail, combining on-site practice and verified data.

Root Causes of Frequent Malfunctions

Most operators only perform repairs after a malfunction occurs, neglecting the small, cumulative problems that build up over time. I once worked at a cardboard factory where their die-cutting machine broke down almost every day. Upon inspection, we found that paper dust was clogging the chain drive mechanism, and the hydraulic system was malfunctioning due to expired lubricating oil. This is not an isolated case—Jiexing's after-sales data shows that 45% of malfunctions are related to environmental contamination, and another 32% are related to improper lubricant use.

Let's look at the main culprits:

- Paper dust accumulation: Waste edges and paper dust generated during die-cutting can enter moving parts, clogging photoelectric sensors and jamming the intermittent mechanism.

- Improper lubrication: Using the same lubricant for the main drive and intermittent mechanism box can lead to insufficient lubrication or inappropriate lubricant viscosity.

- Mechanical fatigue: Failure to replace aging gear springs and worn friction plates in a timely manner can lead to reduced accuracy and clamping problems.

- Electrical faults: Dust on electrical switches can interfere with PLC control logic and affect signal transmission.

Jiexing's Solutions

1. Precision Design to Mitigate Environmental and Mechanical Risks

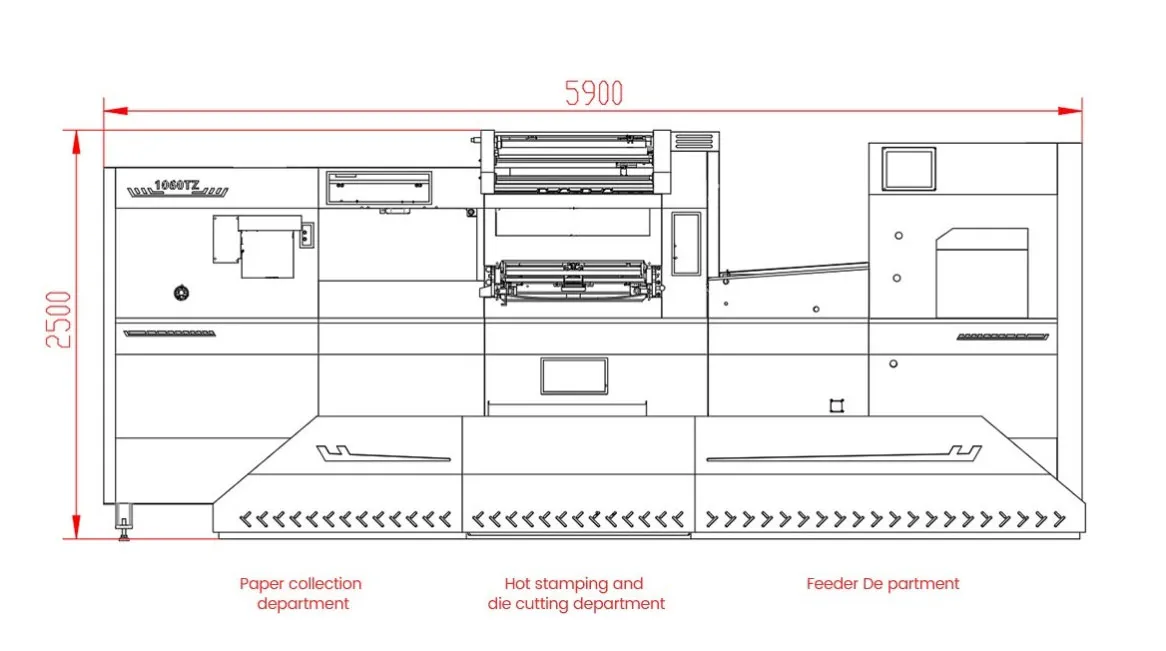

Jiexiang's automatic flatbed die-cutting machines feature a fully enclosed dust-proof structure—effectively blocking 98% of paper dust from entering core components. We conducted a comparative test: Jiexiang equipment versus a standard model, running continuously for 8 hours at a speed of 6000 sheets per hour. The failure rate of the Jiexiang equipment was only 0.05%, while the failure rate of the standard equipment was as high as 1.2%. Its integrated lubrication system is also highly intelligent – it automatically delivers Shell Omara 100 lubricant to the main drive and 220 lubricant to the intermittent mechanism box, so you don't have to worry about manually mixing lubricants (which, by the way, is a common mistake).

For wear-prone parts like the gear rack, Jiexiang uses high-fatigue-resistant springs – their lifespan is three times that of standard springs. After a high-end packaging factory switched to Jiexing equipment, guess what? They experienced zero gear rack-related failures in 12 months. This completely solved their previous problems with die-cutting errors caused by insufficient clamping force.

2. Customized Parameter Matching and Intelligent Early Warning

Different materials and carton types require different parameter adjustments – there's no one-size-fits-all solution. Jiexiang provides customized parameter settings: their engineers analyze the material thickness, hardness, and surface characteristics to create a dedicated die-cutting pressure and speed curve. For smooth coated paper, they even optimized the gear rack clamping structure, increasing friction by 40%, thus eliminating positioning drift.

Jiexiang's intelligent PLC system monitors 16 key indicators in real time. If the lubricant deteriorates or paper dust accumulates to dangerous levels, the system immediately issues an alarm – preventing sudden shutdowns. A food packaging factory used this feature and reduced unplanned downtime by 65% – a huge improvement for production.

3. CE Certified Safety and Systematized Maintenance

All Jiexiang automatic die-cutting machines comply with the EU Machinery Directive CE certification and provide complete risk assessment reports and technical documentation. Safety interlocks and overload protection functions react quickly – if an object falls into the die-cutting area, the machine will automatically shut down, preventing serious mechanical damage.

Jiexiang's after-sales team also provides quarterly on-site maintenance training. They develop personalized maintenance checklists based on different configurations – for example, for high-volume production workshops and small custom workshops. The training covers the basics: cleaning paper dust, knowing when to change lubricants, and checking the gear rack. After the training, your operators will essentially become on-site maintenance experts.

Say goodbye to frequent breakdowns with Jiexing equipment.

Frequent die-cutting machine failures not only increase maintenance costs but also delay delivery times and damage customer trust. Jiexiang integrates precision manufacturing, intelligent technology, and customized services to create reliable equipment for printing and packaging companies. Whether you're looking to solve existing problems or seeking new equipment, Jiexiang can meet your needs. Whatever equipment you require, our one-stop solutions have you covered.

Don't let equipment malfunctions slow down your production. Learn more about Jiexiang's full range of automatic die-cutting machines today, or contact our technical team for a free on-site diagnostic service.