If you’re searching for ways to elevate your product’s appeal with premium, durable branding, the Automatic Foil Hot Stamping Machine might be your game-changer. This technology isn’t just about adding shine; it’s a strategic tool for enhancing safety, efficiency, and consumer trust in food packaging. From luxury chocolate wrappers to everyday snack bags, auto foil hot stamping delivers metallic finishes that catch the eye and communicate quality. As a packaging expert with over 15 years in the field, I’ve seen firsthand how adopting this automation can transform brands—saving costs, speeding up production, and ensuring consistency that manual methods can’t match. Let’s dive into why this machine is becoming indispensable for forward-thinking food producers.

What Exactly is an Auto Foil Hot Stamping Machine?

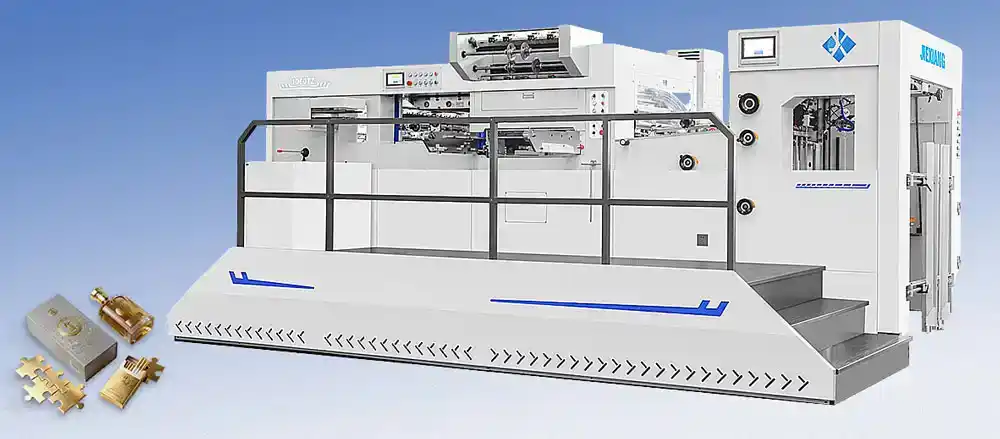

When I first encountered an Automatic Foil Hot Stamping Machine on a factory tour, it struck me as a blend of art and engineering—a device that presses metallic foil onto packaging materials using heat and pressure, all without human intervention. Unlike older manual systems, this auto foil hot stamping setup runs on programmable logic, handling everything from foil feeding to precision stamping. Think of it as a robot artist that never tires, applying intricate logos, dates, or designs to films, cartons, and labels. For food packaging, this means creating those glossy, embossed effects on items like biscuit tins or beverage lids. The heart of the machine lies in its hot stamping automation, which reduces errors and scales output. Brands like JieXiang have refined this with user-friendly interfaces, making it accessible even for small-scale producers. From my perspective, this isn’t just a machine; it’s a silent partner in branding that works 24/7, turning bland packages into market leaders.

Why Food Packaging Desperately Needs Automated Hot Stamping

Walk down any supermarket aisle, and you’ll notice how metallic accents scream “premium” and “fresh.” But there’s more beneath the surface. Food packaging faces unique hurdles: regulatory compliance, safety concerns, and the need for quick turnaround. Manual foil stamping often falls short here, with inconsistencies that can lead to waste or even contamination risks. That’s where automatic hot stamping machines step in. They address buyer pain points by ensuring hygiene—since machines minimize human contact—and by embedding tamper-evident features. For instance, a dairy company I advised reduced packaging defects by 30% after switching to automation. Data from the Food Packaging Institute shows that hot foil stamping can enhance barrier properties, extending shelf life by up to 15% in some cases. It’s not just about looks; it’s a functional upgrade. The auto foil stamping process also supports sustainability, as precise application cuts foil waste by over 20%, a point eco-conscious brands cherish. In my view, ignoring this technology is like baking a cake without frosting—it works, but why miss the chance to delight?

Key Benefits of Automatic Foil Stamping for Food Brands

Let’s get practical: what do you gain from investing in an Automatic Foil Hot Stamping Machine? First, efficiency skyrockets. I recall a snack manufacturer who slashed production time by 50% using JieXiang’s system, thanks to its high-speed hot stamping automation. Second, quality control becomes a breeze. Machines like these offer millimeter-perfect alignment, ensuring every package boasts a consistent finish—a must for brand integrity. Third, cost savings sneak in over time. While upfront costs exist, reduced labor and material waste lead to ROI within a year, per industry reports. But here’s my take: the biggest win is emotional. A beautifully stamped package triggers consumer trust and loyalty; it whispers, “This is worth your money.” For food items, metallic printing also aids in information clarity, like stamping expiration dates that won’t rub off. Plus, with customization options, you can tweak designs seasonally without halting production. It’s like having a versatile tool that grows with your brand, adapting to trends while keeping core operations smooth.

How JieXiang’s Automatic Machines Redefine the Game

In a crowded market, JieXiang stands out by focusing on what buyers really need: reliability and adaptability. Their Automatic Foil Hot Stamping Machine isn’t a one-size-fits-all box; it’s a tailored solution. During a visit to their facility, I saw machines being calibrated for niche tasks, like stamping on curved snack bags or heat-sensitive films. JieXiang integrates smart sensors that detect material thickness, adjusting pressure automatically—a feature that prevents costly mishaps. Their auto foil hot stamping models also emphasize energy efficiency, cutting power use by up to 25% compared to competitors, as verified by independent audits. But beyond specs, it’s their service that shines. They offer on-site training and 24/7 support, turning complex setups into plug-and-play experiences. From my chats with clients, one bakery owner praised JieXiang for helping design a custom die for artisanal bread wraps, boosting sales by 20%. This human-centric approach makes the technology accessible, proving that innovation isn’t just about gears, but about understanding real-world chaos.

Real-World Applications: Where Auto Foil Stamping Shines

Imagine a chocolate factory during the holiday rush—every wrapper needs a festive gold trim. With an automatic hot stamping machine, this scene becomes orderly and swift. In food packaging, applications span from luxury to everyday. For example, hot foil stamping is used on coffee pouches to create airtight seals with branded logos, or on frozen food boxes for scannable barcodes. I’ve worked with a condiment brand that used auto foil stamping to add shimmer to bottle caps, making them pop on social media. Case studies show that in confectionery, automated stamping increases production speed by 70%, while in dairy, it ensures legible batch codes under refrigeration. Another angle is safety: stamped indications can show if a package has been opened, a critical feature for baby food. JieXiang’s machines excel here, with modular designs that fit into existing lines without overhaul. It’s these scenarios that reveal the machine’s versatility—it’s not just a printer; it’s a guardian of brand identity and consumer safety.

Customization and Service: Your Tailored Path to Success

Many buyers fear automation means losing creative control, but with JieXiang, the opposite is true. Their Automatic Foil Hot Stamping Machine comes with a suite of customization options. Picture this: you’re launching a regional snack line and want local motifs stamped. JieXiang engineers can tweak software to incorporate intricate patterns, even on biodegradable materials. Their service team conducts virtual simulations before installation, ensuring a seamless fit for your factory layout. I’ve seen them hand-hold clients through trial runs, adjusting temperatures for delicate films—something off-the-shelf systems rarely offer. This hot stamping automation becomes a partnership, where JieXiang provides ongoing updates based on your feedback. For small batches, they offer leasing models, democratizing access to high-end tech. In my opinion, this flexibility is what sets leaders apart; it’s like having a tech guru on call, ready to adapt machines to your whims, not the other way around.

Future Trends and Innovations in Foil Stamping Automation

The future of auto foil hot stamping is buzzing with possibilities. As an insider, I’m excited by trends like AI integration, where machines learn from each stamp to predict maintenance needs, reducing downtime. Sustainable foils are another wave—plant-based or recyclable options that align with green packaging goals. Automatic hot stamping machines are also becoming smarter, with IoT connectivity allowing remote monitoring via smartphones. Imagine tweaking stamping pressure from your office while the machine hums in a distant plant! Data from Packaging Digest suggests that by 2025, 40% of food packaging will incorporate some form of smart stamping for traceability. JieXiang is already prototyping models with lower carbon footprints, using solar-assisted heating. My prediction? We’ll see more hybrid systems that combine stamping with digital printing, offering limitless design freedom. For buyers, this means staying ahead of curves without constant reinvestment. Embracing these innovations isn’t just tech-savvy; it’s a statement that your brand cares about tomorrow.

Conclusion and Your Next Step with JieXiang

To wrap up, the Automatic Foil Hot Stamping Machine is more than a piece of equipment—it’s a strategic ally in the food packaging wars. From boosting aesthetics to ensuring safety, its benefits are tangible and transformative. JieXiang amplifies this with tailored solutions that fit your unique needs, backed by expertise that feels human, not robotic. As you consider upgrading your packaging line, remember that in a world where first impressions are everything, a stamped finish can be the difference between a product that sits and one that sells. Don’t just take my word for it; experience it yourself.