Having helped first-time hot stamping buyers over the years, I know getting started with an Automatic Hot Stamping Machine can feel pretty overwhelming. There are practical questions about setup, operation, and avoiding common snags that hardly ever get mentioned in basic product descriptions. This article breaks down key points to clear those doubts and help you run the machine smoothly—focusing only on what new users actually need to know.

What Preparations Are Necessary Before Starting an Automatic Hot Stamping Machine?

Before hitting the power button, two critical checks will save you headaches later.

First, make sure your hot stamping foil works with your target material. Foil made for paper, for example, won’t stick right to plastic or cardboard; mismatching these nearly always causes patchy stamping or peeling foil.

Second, give the machine’s key parts a quick check: ensure the stamping plate is locked tight, the feed mechanism is clean (no leftover foil or dust), and all power/control cables are plugged in properly. These pre-use checks take two minutes but save hours of troubleshooting.

How to Avoid Common Operation Mistakes with an Automatic Hot Stamping Machine?

First-timers nearly always trip up on two mistakes: botching temperature settings and ignoring pressure adjustments. A lot of people think “higher temperature = better stamping”—that’s a big mistake. Too hot, and you’ll burn material or melt foil; too cold, and patterns will be faint or incomplete. Start with the temperature your foil/material supplier recommends, then adjust it bit by bit until it’s right.

The other mistake is skipping pressure checks. Too light, and foil won’t transfer fully; too heavy, and you’ll damage both material and stamping plate. Test with a small batch of your material first, tweaking pressure in tiny increments until stamping is clear and even. No need to rush—spending five minutes testing saves you from wasting a whole batch later.

What Routine Maintenance Helps Keep an Automatic Hot Stamping Machine Working Well?

Regular, easy maintenance keeps these machines reliable for years—and it’s simpler than most folks realize. After each use, turn off power, wait for the stamping plate to cool, then wipe it with a soft cloth to remove foil residue. That residue builds up and causes uneven stamping if left.

Once a month, check moving parts like feed rollers. If they feel stiff, add a small amount of machine-specific lubricant to keep them smooth. Skip harsh cleaners—they’ll scratch the machine’s surface or harm internal components. These small steps prevent unexpected breakdowns that mess up your workflow.

What Safety Tips Should You Follow When Using an Automatic Hot Stamping Machine?

Safety’s one of those things folks skip until something breaks—but it’s non-negotiable. Never touch the stamping plate or other heated parts while the machine’s on; they get hot enough to cause serious burns. If you need to adjust something mid-operation, wear heat-resistant gloves. Better yet, turn the machine off first.

Before starting, find the emergency stop button and confirm you know how to use it—feed mechanism jams do happen, and you’ll want to shut things down fast. Also, keep flammable items away from the machine. It’s a small step but slashes fire risks a lot.

Conclusion

By avoiding common operating errors, performing basic maintenance, and following safety guidelines, you can avoid major issues when using an Automatic Hot Stamping Machine for the first time. These steps will not only ensure excellent hot stamping results, but also protect the machine and yourself.

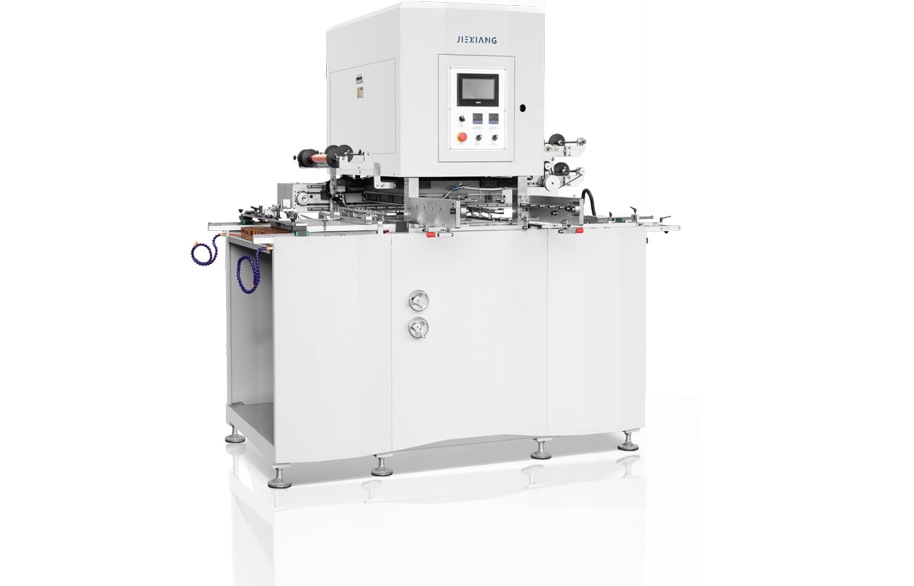

If you are looking for a reliable Automatic Hot Stamping Machine, you can refer to Our Product series to provide you with reliable industry information.