Foil hot stamping gives products that premium, polished look—but it only works if you pair the right equipment with your material. Pick the wrong one, and you'll end up with uneven stamping, damaged materials, or wasted foil. This guide breaks down how to choose the right machine by focusing on what makes common materials unique, so you can avoid mistakes and get consistent, great results.

Start with Understanding Your Material's Properties

The first rule of picking a Foil Hot Stamping Machine? Know your material. Different materials react differently to heat, pressure, and stamping speed—and those reactions tell you exactly what features your machine needs. Below's a breakdown of the most common materials and what to look for.

Paper and Cardboard

Paper and cardboard are the go-to for foil stamping, but they're not all the same. Thin paper tears easily if you apply too much pressure. Thick cardboard, on the other hand, needs enough pressure to make sure the foil sticks evenly.

For these materials, find a machine with adjustable pressure—something that lets you tweak it to match how thick your paper or cardboard is. Stable temperature matters too: too much heat yellows thin paper, so steer clear of machines that have random heat spikes.

Plastics

Plastics—PVC, PP, PET—each have their own melting points. That means temperature control isn't just nice to have; it's a must. Low-melt plastics warp if they get too hot, while high-melt ones need enough heat to activate the foil's adhesive.

Look for a machine that lets you adjust temperature precisely—digital controls are best for this. If you're working with textured plastics, a flexible stamping head helps the foil hug the surface, so you don't get spotty coverage.

Leather and Fabric

Leather and fabric are soft, porous, and they don't soak up heat evenly. Genuine leather, for example, can dry out or crack if it sits under high heat too long. Fabric? It might wrinkle or change color.

What you need here is a machine that spreads pressure evenly—this stops hot spots from damaging the material. You'll also want a lower temperature range and slower stamping speed. Slower speed makes sure the foil sticks without ruining the texture.

Metals

Metals—things like aluminum sheets or metal packaging—are rigid and conduct heat fast. That means your machine needs to heat up quickly to transfer the foil properly, but also cool down fast. If it stays hot too long, the foil peels right off.

Machines for metals need two key things: a heating system that works fast, and strong pressure. Metal's hard, so you need enough force to make sure the foil bonds securely.

Two More Machine Features That Matter for Any Material

Beyond what your specific material needs, there are two features that make or break stamping success—no matter what you're working with.

Precise Temperature Control

Every material has a “sweet spot" temperature. A machine that offers accurate, steady control—not just basic on/off settings—will keep you right in that sweet spot. This is especially important for plastics and leather; even small temperature shifts can ruin your work.

Flexible Pressure Adjustment

How much pressure you need depends on how thick or hard your material is. A machine that lets you fine-tune pressure in small increments works for everything—from thin paper to thick metal. If the pressure settings are fixed, you'll be limited to just a few materials, and that lowers the machine's value.

Conclusion

Picking the right Foil Hot Stamping Machine isn't about choosing the “best" machine—it's about choosing the one that fits your material. Match the machine's temperature control, pressure, and speed to what your material needs, and you'll get consistent, high-quality results every time. Focus first on features that work for your main material; that way, you're not paying for extras you don't need.

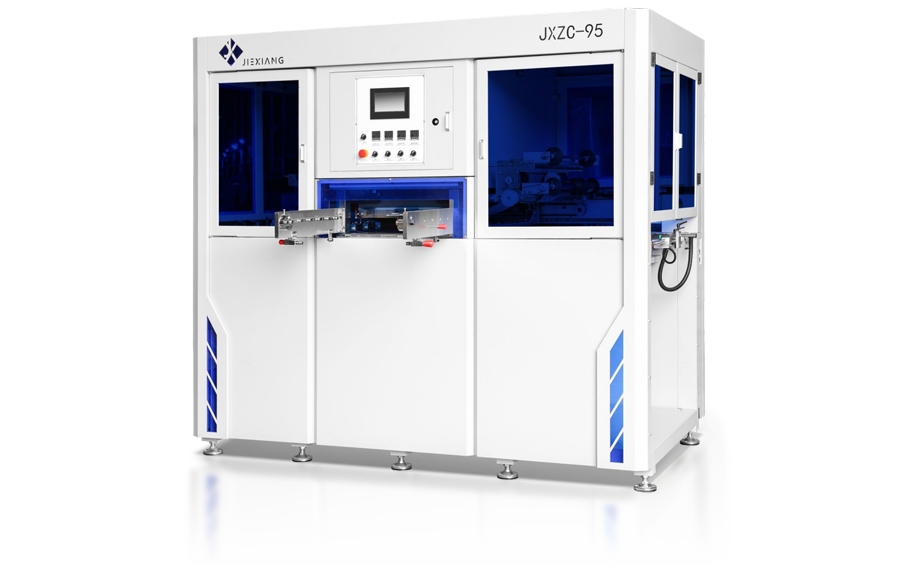

If you have decided on your material type but are unsure how to choose the right Foil Hot Stamping Machine, please contact our team of experts to provide you with professional technical support and find the model that suits your workflow.