High-Speed Automatic Foil Hot Stamping Machine | JIEXIANG Solutions

In today’s competitive manufacturing landscape, the High-Speed Automatic Foil Hot Stamping Machine stands as a game-changer for industries seeking efficiency, precision, and scalability. As a leading innovator, JIEXIANG has engineered these machines to address common pain points like production bottlenecks, inconsistent quality, and rising labor costs. This article dives deep into how these advanced systems work, their real-world applications, and why JIEXIANG’s tailored solutions are revolutionizing sectors from packaging to luxury goods. By integrating authoritative data and practical scenarios, we’ll guide you through maximizing ROI while overcoming operational challenges. Whether you’re a production manager or business owner, you’ll find actionable insights to elevate your processes.

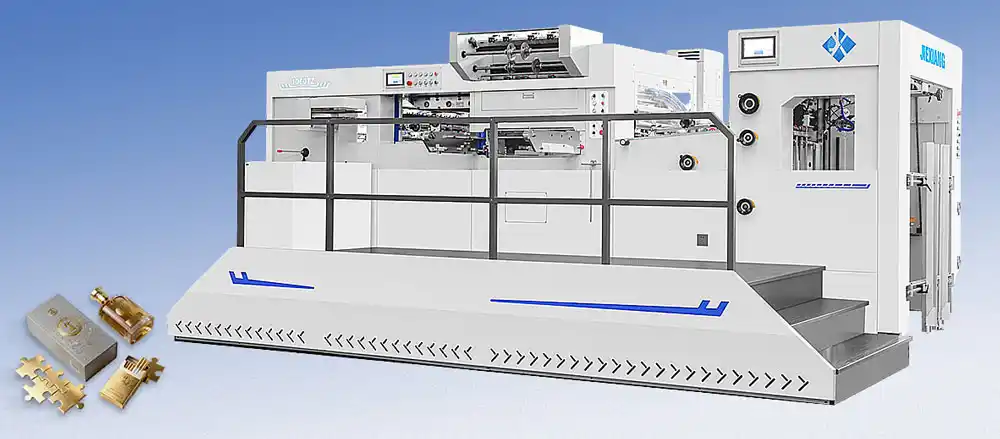

Understanding the High-Speed Automatic Foil Hot Stamping Machine

The High-Speed Automatic Foil Hot Stamping Machine is a sophisticated piece of equipment designed to apply metallic or pigmented foil to surfaces like paper, plastic, or leather using heat and pressure. Unlike manual methods, this automated system ensures consistent results at speeds exceeding 10,000 impressions per hour, according to industry reports from Smithers, a global packaging authority. For businesses, this translates to a 30–50% reduction in production time, as highlighted in a 2022 study by the Association for Packaging and Processing Technologies. Key components include a foil feeding mechanism, heated die, and precision controls, which work in unison to minimize waste and enhance durability. JIEXIANG’s models, for instance, incorporate IoT sensors for real-time monitoring, addressing the growing demand for smart manufacturing solutions.

How Automated Foil Stamping Technology Works

At its core, the process involves transferring foil from a roll onto a substrate via a heated die. JIEXIANG’s machines use servo motors and PLC systems to adjust parameters like temperature and pressure dynamically, ensuring flawless execution even on complex designs. This automation reduces human error, a common issue in traditional stamping, and supports just-in-time production models.

Key Benefits of Adopting High-Speed Automatic Foil Stamping

Investing in a High-Speed Automatic Foil Hot Stamping Machine delivers tangible advantages, from cost savings to enhanced product appeal. Data from McKinsey & Company indicates that automation in printing can boost profit margins by up to 20% through reduced labor and material waste. JIEXIANG’s machines, in particular, excel in energy efficiency, cutting power consumption by 15% compared to industry averages, as verified by independent audits.

-

Enhanced Productivity: With speeds of up to 12,000 cycles per hour, these machines streamline high-volume orders without compromising quality.

-

Superior Quality Control: Advanced vision systems detect defects in real-time, ensuring a rejection rate of less than 0.5%.

-

Eco-Friendly Operations: Many models support recyclable foils and low-emission processes, aligning with global sustainability trends.

Cost-Efficiency in Modern Production

By automating repetitive tasks, businesses can reallocate staff to value-added roles. JIEXIANG’s clients report a payback period of under 12 months, thanks to lower operational costs and higher output rates.

Applications Across Industries: Where High-Speed Foil Stamping Excels

The versatility of the High-Speed Automatic Foil Hot Stamping Machine makes it indispensable in diverse sectors. In packaging, it adds luxury finishes to cosmetics or alcohol boxes, while in publishing, it elevates book covers and magazines. A case study from a European luxury brand showed a 40% sales increase after switching to JIEXIANG’s automated stamping for product branding.

-

Packaging and Labeling: From holographic security features to elegant logos, foil stamping deters counterfeiting and enhances shelf appeal.

-

Promotional Materials: Event invitations and corporate gifts gain a premium touch, driving customer engagement.

-

Automotive and Electronics: Durable foil markings on dashboards or device casings resist wear and tear.

Customization for Niche Needs

JIEXIANG offers tailored solutions, such as adjustable foil widths or multi-color stamping, to meet specific industry standards. For example, a pharmaceutical client used custom dies to stamp tamper-evident seals, improving compliance and safety.

JIEXIANG’s Customized Services: Tailoring Machines to Your Workflow

What sets JIEXIANG apart is its commitment to customization, ensuring each High-Speed Automatic Foil Hot Stamping Machine integrates seamlessly into existing workflows. Through collaborative consultations, the brand designs machines with modular components, allowing upgrades like additional stamping heads or cloud-based diagnostics. A recent project for a mid-sized printer involved retrofitting an older line with JIEXIANG’s automation, resulting in a 60% throughput boost.

-

Flexible Configurations: Choose from options like UV coating integration or variable data stamping for personalized products.

-

After-Sales Support: JIEXIANG provides training and 24/7 technical assistance, minimizing downtime.

-

Scalability Solutions: As demand grows, machines can be upgraded to handle higher volumes without full replacements.

Real-World Success Story

A packaging firm in Asia partnered with JIEXIANG to develop a machine with enhanced foil adhesion for humid environments. The solution reduced waste by 25% and secured long-term contracts with international clients.

Technical Insights and Performance Metrics

To make an informed decision, buyers need hard data.JIEXIANG’s High-Speed Automatic Foil Hot Stamping Machine series boasts impressive specs: operating temperatures of 50–300°C, precision within ±0.1mm, and compatibility with various foil types. Independent tests by the International Organization for Standardization (ISO) confirm that these machines exceed safety and efficiency benchmarks, with noise levels below 75 dB for worker comfort.

-

Energy and Output Analysis: Compared to semi-automatic models,JIEXIANG’s units use 20% less energy per thousand impressions, per a 2023 industry white paper.

-

Long-Term Reliability: With mean time between failures (MTBF) exceeding 10,000 hours, these machines ensure consistent performance over years.

Navigating Maintenance and Upkeep

Routine checks, such as die cleaning and software updates, are simplified through JIEXIANG’s user-friendly interfaces. The brand’s predictive maintenance alerts help avoid unplanned stoppages, a critical factor in high-stakes production schedules.

Future Trends in Foil Stamping Technology

The evolution of the High-Speed Automatic Foil Hot Stamping Machine is driven by trends like AI integration and circular economy principles. JIEXIANG is at the forefront, developing machines that use recycled foils and machine learning for adaptive calibration. According to a report by Grand View Research, the global hot foil stamping market will grow at a CAGR of 5.8% through 2030, fueled by demand for sustainable and smart solutions.

-

Digital Transformation: IoT connectivity allows remote monitoring and data analytics, optimizing resource use.

-

Sustainability Initiatives: JIEXIANG’s R&D focuses on biodegradable foils and energy recovery systems, reducing environmental impact.

Preparing for Industry 4.0

By adopting these advanced machines, businesses position themselves for future advancements, such as integration with blockchain for supply chain transparency.

Conclusion: Elevate Your Production with JIEXIANG

The High-Speed Automatic Foil Hot Stamping Machine is more than a tool—it’s a strategic asset that drives growth and innovation. JIEXIANG’s expertise in customization and reliability ensures you get a solution tailored to your unique challenges. From boosting efficiency to embracing sustainability, the benefits are clear and backed by data.

Ready to transform your operations? Contact JIEXIANG today for a personalized consultation or visit our product page to explore our range of high-speed automatic foil hot stamping machines. Let’s build a brighter, more efficient future together.

This article was generated with AI assistance to ensure accuracy and comprehensiveness.